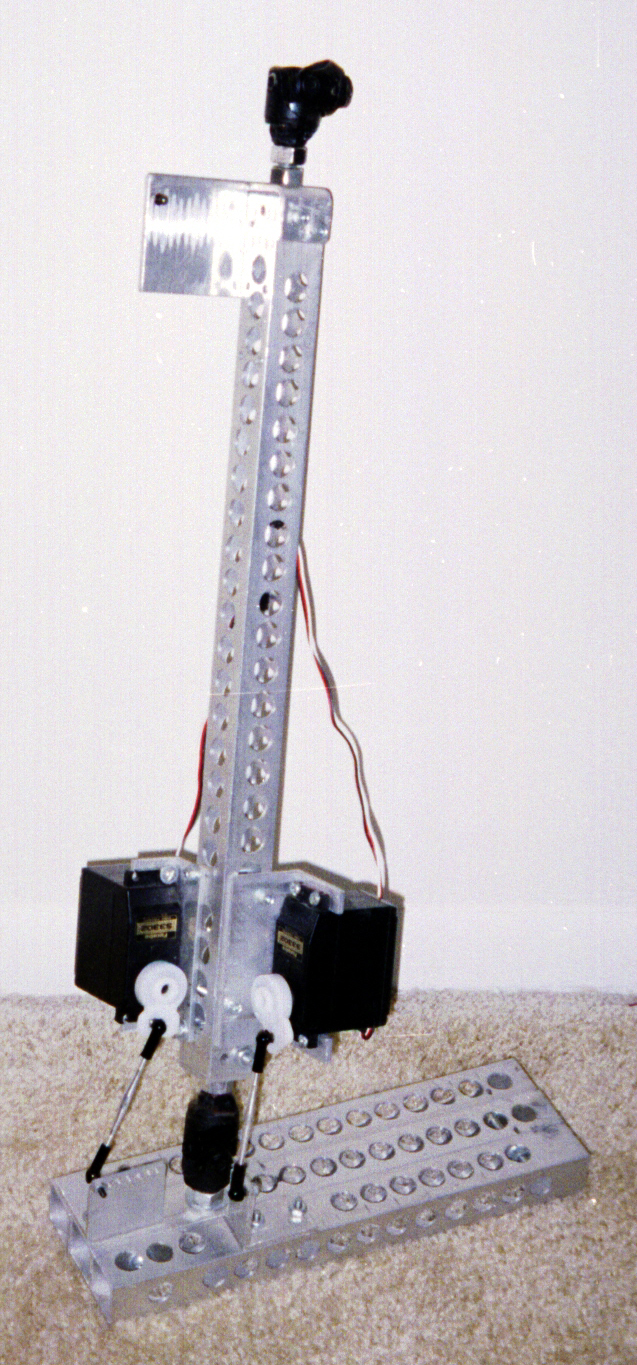

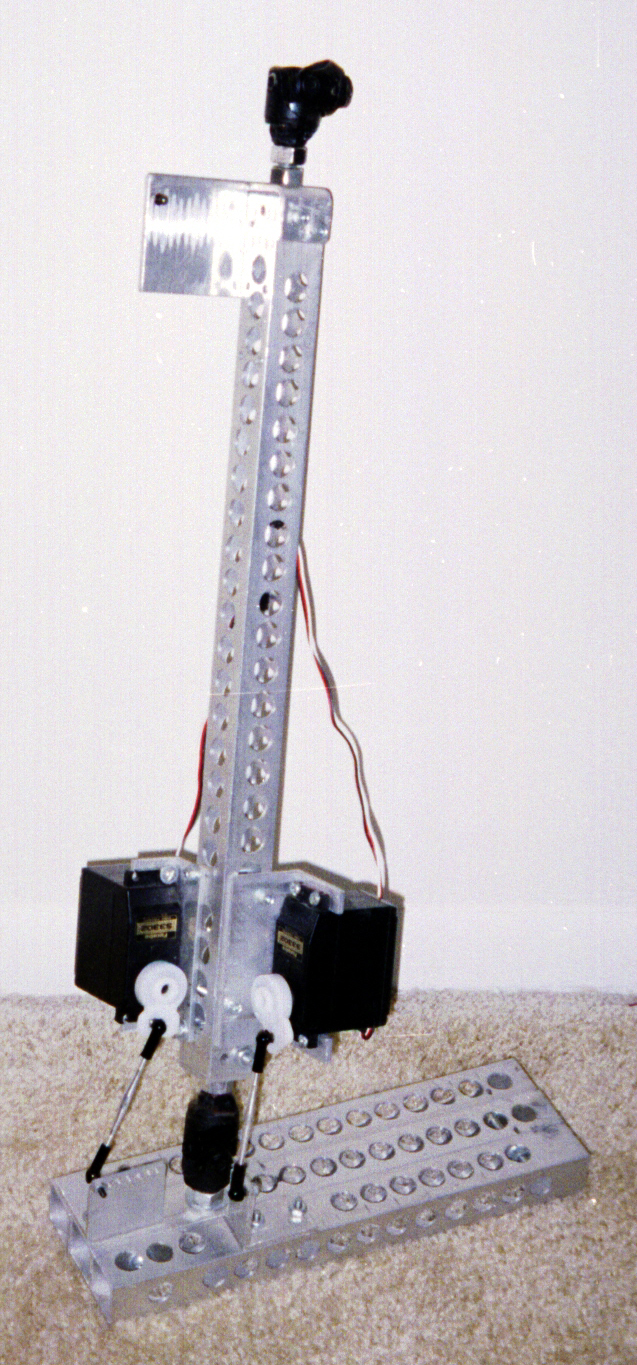

Achilles left foot, calf and knee. The ankle joint is identical

to the knee joint: both are made from

identical Lovejoy universal joints. Custom modifications include

weight/size reduction and a nut welded

onto each end into which lower and upper components bolt into.

Since the knee joint only requires

one axis of rotation, one of the bolts is tightened maximally into

the universal joint central hub, thus

constraining one axis of rotation. This simple design will allow

for a reversal in time when the u-joint

wears so that it's effectively it's own spare! A fine design

if I say so myself. The design of Achilles

foot motor placement differes from Alf's: Alf had one servo above and

one below the u-joint. Achilles

has both above. Putting both on the same side impacts servo

independence: I prefer Alf's design, but

Achilles servos are so large that the other won't fit below the u-joint

(well, I might try it one more time).

The keen observer will note the ball-joint of the side servo is aligned

right through the axis of rotation

of the u-joint. In Alf, both ball-joint attach points have this

feature. On Achilles, only one (side) has

this feature because the other servo isn't below the u-joint.

In addition to the use of Aluminum for

light weight, 220 weight-reducing holes were drilled in the foot and

calf.

Copyright © 1999 Patrick M. Rael

All rights reserved